Unlocking Innovation: The Power of Rapid Prototyping in Metal Fabrication

In an era where innovation dictates success, businesses are continually searching for more efficient methods to bring their concepts to life. Among these, rapid prototyping has emerged as a game-changing strategy for the metal fabrication industry. This article delves deep into what rapid prototyping is, its advantages, applications, and its transformative role in driving efficiency and effectiveness in business. With the growing need for speed and precision, understanding this concept is essential for businesses looking to stay ahead.

What is Rapid Prototyping?

Rapid prototyping is a collection of techniques used to quickly fabricate a scale model of a physical part or assembly using 3D computer-aided design (CAD) data. This can include various processes such as:

- 3D printing

- CNC machining

- Injection molding

- Laser cutting

These methods are not just limited to producing models; they allow for the iterative testing and refinement of designs which can lead to improved functionality and performance of the final product.

The Importance of Rapid Prototyping in Metal Fabrication

Metal fabrication is a complex process that involves various stages, including design, production, and finishing. Integrating rapid prototyping into this process holds numerous benefits:

1. Enhanced Design Flexibility

With rapid prototyping, engineers and designers can create multiple iterations of a product in a fraction of the time it traditionally takes. This flexibility enables:

- Quick modifications based on testing and feedback

- Experimentation with various materials and designs

- Faster response times to market demands

2. Cost Efficiency

Creating prototypes using conventional methods can be expensive and time-consuming. Rapid prototyping drastically reduces labor costs and material wastage because:

- Prototype production requires less time than traditional methods

- Initial designs can be tested quickly, minimizing investments in unusable designs

- Reduces the need for extensive tooling, which is costly and takes significant lead time

3. Accelerated Time-to-Market

In today’s competitive landscape, being first to market is crucial. Rapid prototyping enables companies to:

- Develop and launch products faster

- Improve collaboration between teams through rapid feedback loops

- Streamline the entire design and production process

Applications of Rapid Prototyping in Metal Fabrication

The applications of rapid prototyping span various sectors, illustrating its versatility:

1. Aerospace Industry

In aerospace, components must meet strict safety and regulatory standards. Rapid prototyping allows engineers to test designs in real conditions before committing to production, ensuring every part meets the required specifications.

2. Automotive Sector

Automakers use rapid prototyping to design everything from engine components to body structures. This method allows for:

- Rapid testing of both function and aesthetic

- Reduced cycle times for vehicle design

- Incorporation of consumer feedback into new models quickly

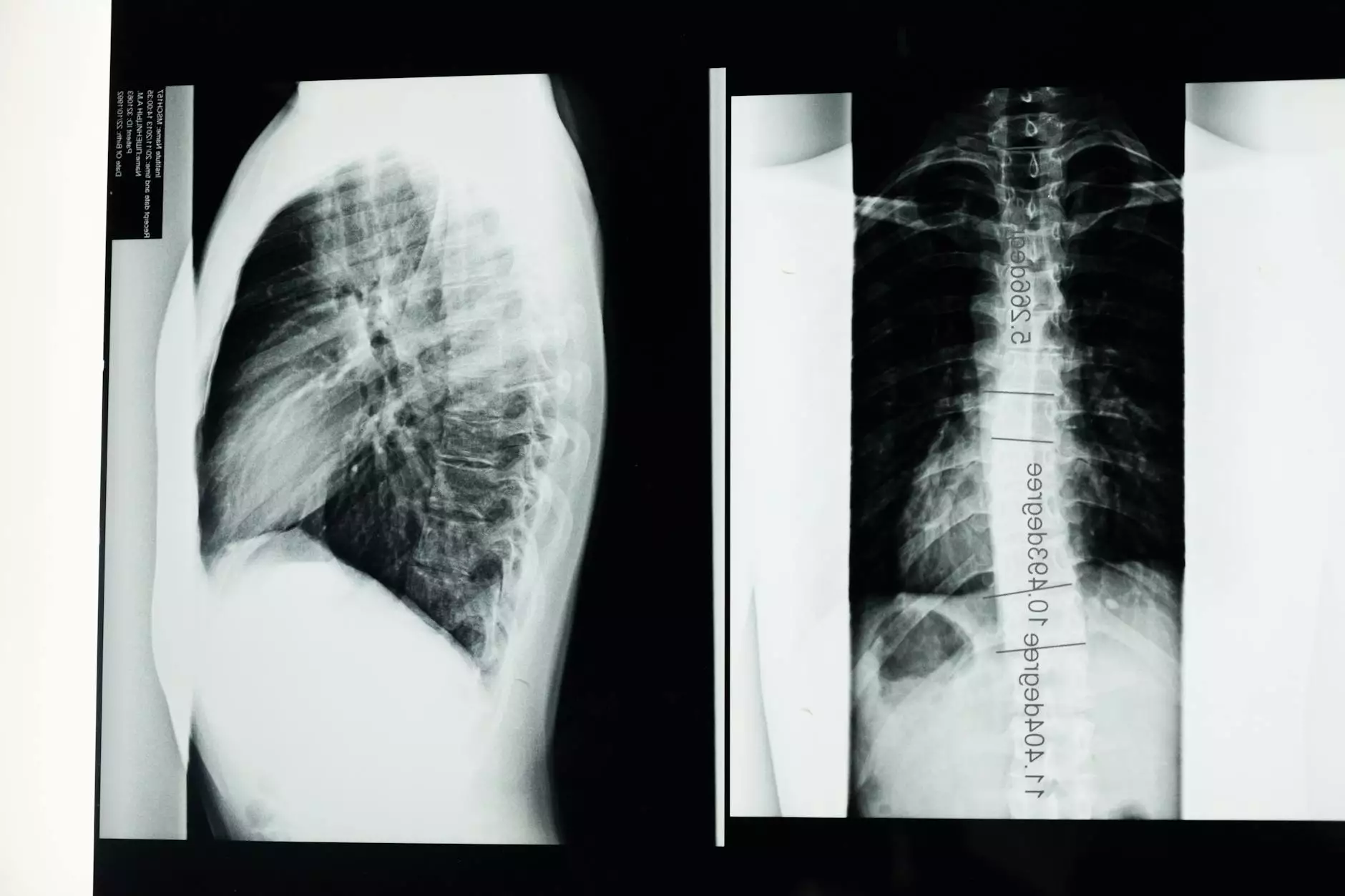

3. Medical Devices

The medical field benefits immensely from rapid prototyping. Customized medical devices can be created quickly, facilitating:

- Personalized solutions for patients based on specific anatomical needs

- Faster development of new surgical tools and implants

- Enhanced collaboration between design teams and medical professionals

Future Trends in Rapid Prototyping

As technology evolves, so too does rapid prototyping. Here are some emerging trends to watch:

1. Integration of AI and Machine Learning

Artificial intelligence is set to revolutionize the design process. By integrating AI into rapid prototyping, manufacturers can:

- Create smarter designs through predictive analysis

- Adapt designs in real-time based on testing data

- Optimize production schedules and material usage

2. Sustainable Practices

As sustainability becomes a priority, rapid prototyping can help reduce waste. Techniques such as:

- Additive manufacturing

- Use of eco-friendly materials

Enable businesses to minimize their environmental impact while still customizing their products efficiently.

3. Improved 3D Printing Technologies

Advancements in 3D printing technology will enhance the speed and quality of rapid prototyping, allowing for:

- Greater detail and precision in prototypes

- Using a wider variety of materials, including metals and composites

Conclusion

As we've explored throughout this article, rapid prototyping represents a pivotal force in metal fabrication. Its capacity for enhancing design flexibility, driving costs down, and accelerating time-to-market is transforming how businesses operate. Companies that adopt this innovative approach position themselves for success, responding agilely to market demands and pioneering new products that meet ever-evolving consumer needs.

For businesses in the field of metal fabrication, the time to invest in rapid prototyping technologies is now. By leveraging the advantages discussed, you can not only streamline your production processes but also foster a culture of innovation that will pave the way for future successes. Join the ranks of forward-thinking companies, and let rapid prototyping be the catalyst that propels your business to new heights.